Water is an irreplaceable resource that sustains us in our daily lives. At Yakult, it is an ingredient in products and also essential for cleaning, cooling and disinfecting plant facilities.

Here we introduce the overall concept of water use at Yakult, as well as our water resource conservation activities around the world.

-

- 6, 12: We conserve water resources by using water in production effectively, and by comprehensively managing wastewater quality.

- 13: We are taking action against climate change-related water risks.

Increase in global population and economic development are driving growth in water use. Intensification of climate change is also closely connected to water resources and is causing extreme weather such as localized changes in rainfall levels, flooding, and drought.

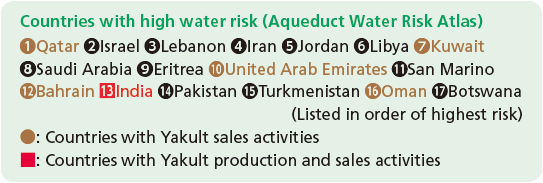

The Aqueduct Water Risk Atlas published by the World Resources Institute (WRI) indicates water risk in areas throughout the world. The below 17 countries are identified as having high water risk, with some of them being home to Yakult production or sales.

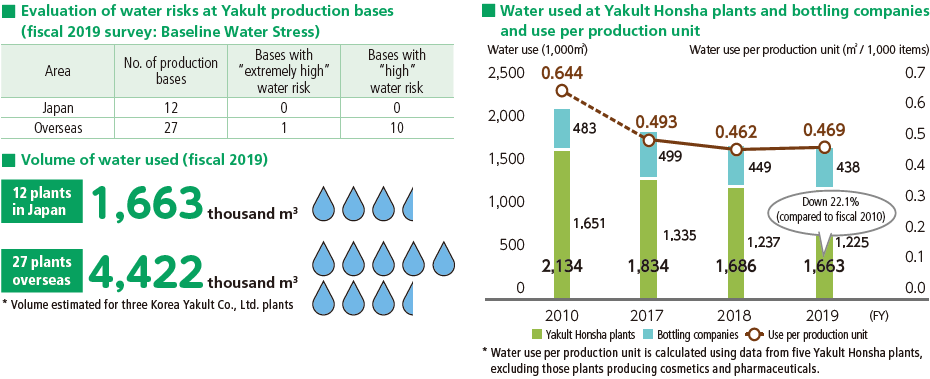

Since 2017, we have been conducting surveys through external organizations to understand the impact each production base has on nearby waterways and ecosystems, as well as flooding and other water risks. In March 2020 we used the WRI Aqueduct Water Risk Atlas tool to evaluate water risks at all production bases. (See table at right)

Based on these results, we are working to ascertain the situation at each location and reflect the findings in our production and policymaking.

We run various water resource conservation initiatives at Yakult production bases, with the following two primary goals:

-

❶ Reduce water use

by reusing water or changing production processes

-

❷ Manage wastewater appropriately

with stringent internal standards and our proprietary A&G Water Purification System

We are striving to reduce water use and manage wastewater appropriately around the world.

Reducing water use with updated equipment and operations

In the past, a certain amount of water use was necessary to maintain a constant flow that cools devices used to close the aluminum caps on Yakult bottles and other products. In fiscal 2019 we installed equipment to reduce that amount by reusing coolant water.

External air conditioning units at some plants are also cooled by spraying water, and changing the volume and time the water is sprayed, and the nozzle shape, has reduced water use while still maintaining operational efficiency.

Emergency training

Knowing the impact our plants can have on the natural environment of surrounding waterways, we hold emergency training at least once per year to prepare workers for unexpected circumstances, such as if oil from transportation vehicles is released into waterways, to improve their awareness and strengthen our systems.

-

Stringent standards for wastewater management

Wastewater at all plants is managed based on voluntary standards more stringent than those stipulated by law.

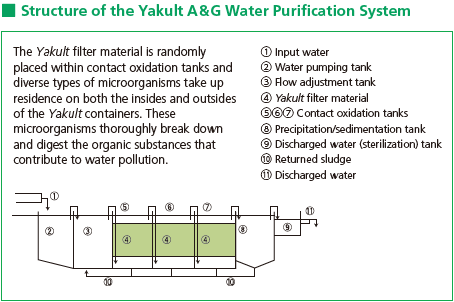

Wastewater is treated appropriately by treatment facilities at each plant or by the A&G Water Purification System, which utilizes the power of microorganisms that attach themselves to Yakult containers, then released into the sewer system or rivers. -

-

Reducing water use with new cooling systems

and wastewater reuse (Yakult S.A. de C.V. (Mexico))When the Yakult Mexico Guadalajara Plant changed the cooling method for its dairy homogenization equipment, they were able to reduce their fiscal 2018 water usage by 1,464㎥ from the previous year —a reduction of more than half.

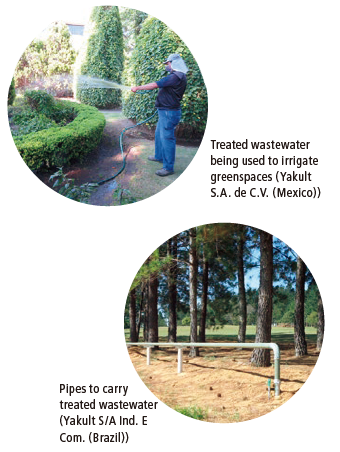

At the Ixtapaluca Plant, water is conserved by reusing treated wastewater for irrigating greenspaces around the facility. In fiscal 2019 irrigation used an average of 775㎥ of water each month, for a yearly total of 9,300㎥.Using treated wastewater to flush toilets

(Yakult S/A Ind. E Com. (Brazil))The Yakult Brazil Lorena Plant has started construction on a system that uses wastewater from Plant 3 and worker welfare facilities to flush toilets. This is expected to result in a large reduction in water use.

-

Providing free plant water when public water services are down (Yakult Philippines, Inc.)

At each production base, Yakult Philippines explains wastewater management to locals during events, keeping in close contact with the community. Some production bases are also equipped to help support local regions in times of disaster.

For example, the Calamba Plant has a system enabling them to provide plant water for free to the local area when public water services are down. In an area with frequent water service issues, where outages and contamination occur often, the plant helps support the safety and security of the local community.