Climate changeMateriality

Our approach

Climate change caused by human economic activity has brought about wide-ranging risks worldwide, from natural disasters to biodiversity loss due to the impacts of global warming, which require urgent global action. We recognize that climate change is a critical issue for the Yakult Group’s business continuity. As global society works toward net zero, the Yakult Group will cut GHG emissions by setting fixed targets, advancing more energy conservation initiatives and actively adopting renewable energy.

Related SDGs

Promoting CO2 reduction

At Yakult Honsha plants and bottling companies, we are reducing CO2 emissions by introducing environmentally conscious equipment, switching to LED lighting and improving production efficiency. We are also actively adopting solar power, a clean and renewable source of energy.

At our 13 domestic plants in particular, we have effectively switched to electricity from renewable energy sources.

Main initiatives

Yakult Group Environmental Vision

The world is experiencing climate change and various other environmental issues that are growing more severe with time. The Yakult Group creates products that are available in 40 countries and regions around the world, and we conduct our business on the basis of local production for local sales. We recognize that our corporate activities have not only positive but also negative impacts on local communities and environments in various locations globally.

In March 2021, the Yakult Group created the Yakult Group Environmental Vision to reduce our negative impacts and promote efforts with a positive impact on the global environment with the aim of uniting people and planet as one. We set out our ideal vision for the future in Environmental Vision 2050 and, using backcasting, established short- and medium-term milestones in order to effectively act and make progress toward this vision.

Reducing CO2 emissions from our manufacturing and marketing departments

At Yakult Honsha plants and bottling companies, we have been reducing CO2 emissions by switching to LED lighting, improving equipment and production efficiency, using solar power generation, and other initiatives. We also changed the pump supplying cold water to storage tanks to operate intermittently, in order to reduce power consumption and CO2 emissions.

We are also introducing electric vehicles to reduce CO2 emissions of delivery vehicles used by Yakult Ladies at marketing companies.

Solar panels at Okayama Wake Plant

Electric vehicle (COMS)

Switching to renewable energy to power our 13 domestic plants

In April 2022, we switched all purchased electricity used in production processes at our 12 domestic plants,* and in July at the Shonan Cosmetics Plant, to electricity almost entirely from renewable energy sources provided by power companies with which we have contracts. This conversion to renewable energy has reduced CO2 emissions by approximately 34,800 tons per year for the 13 plants in total, and is expected to reduce greenhouse gas emissions (in Japan, Scope 1 and 2) by approximately 40% compared to fiscal 2018.

* Fukushima Plant, Ibaraki Plant, Fuji Susono Plant, Hyogo Miki Plant, Saga Plant, Yakult Iwate Plant, Yakult Chiba Plant, Yakult Aichi Plant, Yakult Okayama Wake Plant, Yakult Fukuoka Plant, Fuji Susono Pharmaceutical Plant, Yakult Materials Co., Ltd. Fuji Susono Plant

Note: Electric power-related CO2 emission factors are the adjusted emission factors of each electric power company.

Special

Report

Report from the Frontlines

Growing the sustainable Yakult Forest with our global stakeholders: Yakult Europe B.V.

Growing the sustainable Yakult Forest with our global stakeholders: Yakult Europe B.V.

In 2022, Yakult Europe B.V. has launched a partnership with Treedom, a global web platform to promote the trees planting worldwide with the aim of making the planet greener. Planted trees will be taken care by local farmers over the long term. In this article, one of our staff explains the value of this partnership and future ambition.

Preserving biodiversity and more: Reforestation with Treedom

From a global perspective, Europe is known for its high level of awareness around environmental issues. The European Union has taken the lead in developing environmental laws and regulations, and a range of European corporations continue to implement forward-thinking environmental initiatives. In 2022, Yakult Europe B.V. entered into a partnership with Treedom, a global web platform working to plant trees and expand forests across the globe, to grow the Yakult Forest together with all of our employees. This initiative not only contributes to reforestation, it also has the potential to bring social and economic benefits for local communities in developing nations.

Harvesting oranges in Ecuador

Treedom was established in Italy in 2010. It promotes reforestation through a system where seedlings purchased online are planted and cultivated by local farmers in places like Africa and Central and South America. To date Treedom has partnered with approximately 11,000 companies, with 220,000 farmers in 15 countries having planted 3.8 million trees. There are many tree-planting organizations around the world, but Treedom is unique in both their long-term support for the planted trees and their efforts surrounding forestry conservation and management. For this reason, Treedom’s planting cost per tree is higher than those of other organizations. However, we found noticeable differences compared to other organizations in the way Treedom tackles environmental issues such as biodiversity and climate change, as well as offering the social and economic opportunities to farmers.

Harvesting oranges in Ecuador

A Tanzanian farmer watering young avocado plants

Creating online Yakult Forest community with Yakult employee

While valuing Treedom’s unique activities, it took continuous discussion with corporate communication colleagues in each country to select one organization for partnership. In this internal selection and planning process, we have discussed thoroughly the objective of this partnership and found that vision of Treedom perfectly matches Yakult’s corporate philosophy and Environmental Vision. So we have decided to move forward with the partnership and to start where we can.

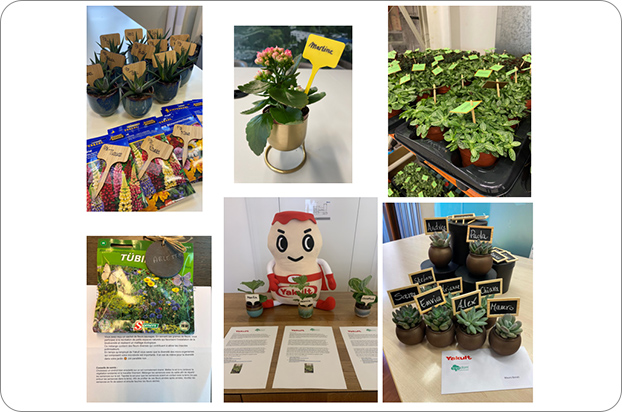

To celebrate this partnership we gifted actual plant with online Treedom code to all Yakult group colleagues in Europe so everyone can choose the type of their trees and country where trees will be planted according to their choice and join Yakult forest on Treedom platform.Through the Yakult Forest page, employees can follow the stories of the growing trees with pictures and geographical information where trees are planted. Internally we have received positive employee feedback that they are happy and excited to see actual action and one step towards better tomorrow.

Plants and Treedom codes gifted to employees

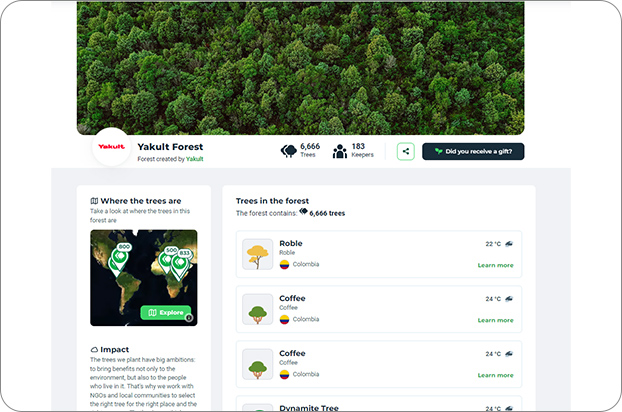

Yakult Forest webpage

Expanding initiatives with a wide variety of stakeholders

We have also worked to maximize this partnership through external communication. We have created press releases which has been announced in each language on local websites across Europe. To further raise awareness of this initiative, we sent out newsletters and promoted it on social media. In addition, we also gifted Treedom codes to our external stakeholders and consumers and offered them the opportunity to join the Yakult Forest community.

Furthermore, in September 2022, Yakult Europe B.V. and the City of Almere in the Netherlands cohosted a CSR seminar at Floriade Expo 2022, international horticulture exhibition. We invited Treedom as one of the speakers to highlight for both internal and external stakeholders the importance of active partnerships to improve society and the environment.

As of June 2023, our partnership with Treedom has resulted in 6,747 trees planted in seven different countries, which is expected to reduce CO2 by 1,880.4 tons.

Ruaha National Park , Tanzania

At Yakult Europe B.V., we will continue striving to grow the Yakult Forest not only with Yakult employees but also through an expanded community of stakeholders.

Employee Comment

Company: Yakult Europe B.V.

Position: Corporate Communication Officer

Name: Miki Niwa

Employee Comment

Our future ambition is to maximize this partnership not only within the Yakult Group, but also by involving our external stakeholders. Treedom offers an unique online platform with attractive photos and videos which lets us share our story and engage even more people in this initiative. By continuing this partnership we can support tangible benefit for people and planet.