Working to procure raw materials responsibly

The Yakult Group’s promotion of sustainable procurement in cooperation with business partners is an important theme in supporting a variety of activities that contribute to the production and sale of products useful for health, and the creation of a sustainable society.

We will continue communicating proactively with our suppliers to evaluate social and environmental impact and reduce risk throughout the supply chain in order to improve the sustainability of society.

Yakult Group Supplier CSR Guidelines

We have established Yakult Group CSR Procurement Policy to commit to responsible procurement and work toward a sustainable society. To effectively promote sustainable procurement even further, in July 2020 we established the Yakult Group Supplier CSR Guidelines. These guidelines summarize our requests for responsible procurement made to all business partners in and outside Japan, including when starting a new partnership. We confirm if business partners are following through with the guidelines using surveys and other measures, and take appropriate steps to improve on any issues that arise.

Improving awareness within the company

For workers involved in raw material procurement and manufacturing consignment, we provide information and training on the CSR Procurement Policy’s objectives and responsible procurement activities for creating a sustainable society.

We hold sustainable procurement study sessions, promotion meetings and workshops to help further the planning and implementation of policies for sustainable supply chain management.

A sustainable procurement promotion meeting

Working with suppliers to manufacture Yakult products

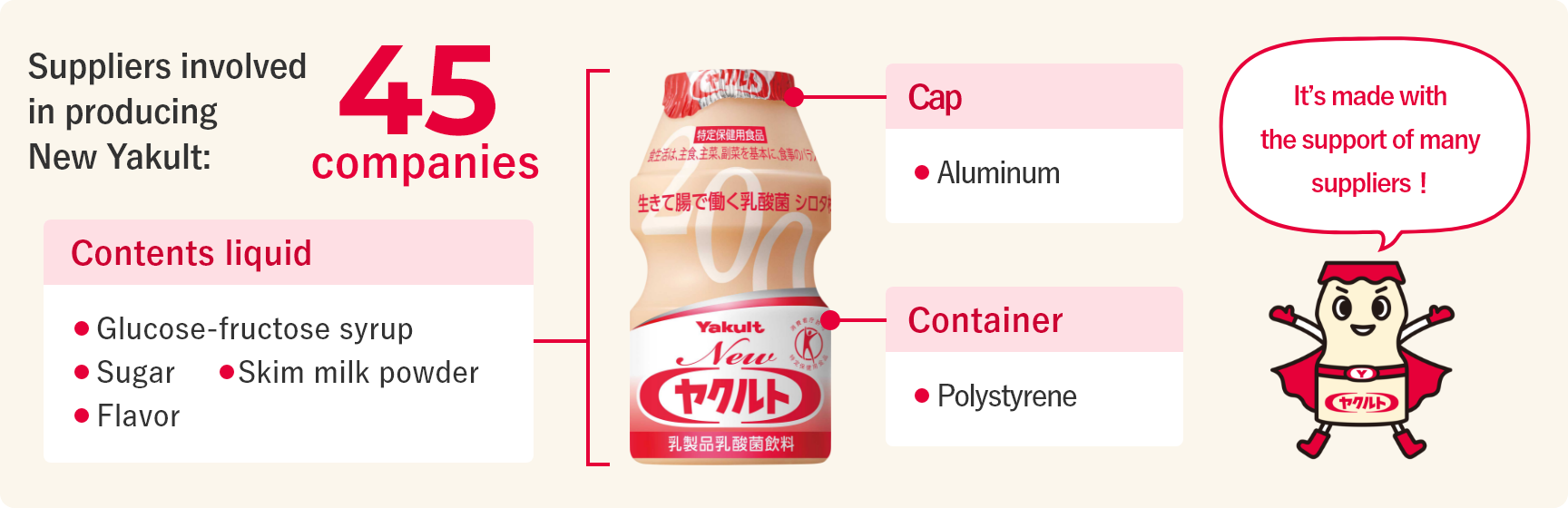

Production of New Yakult

New Yakult is our fermented milk drink with 20 billion Lactobacillus casei strain Shirota bacteria in each bottle (65ml) that reach the intestines alive to improve the intestinal environment. From major companies with over 10,000 workers to small businesses with less than 10, which supply powdered skim milk, flavor, packaging and other materials, the production of New Yakult is supported by a wide variety of business partners.

*Number of primary suppliers (Includes secondary suppliers when primary supplier is a trading company.)

*As of October 2021

Cooperation with suppliers

Stable procurement of

dairy product raw materials

- ・Primary raw materials are purchased from multiple companies to disperse procurement risk

- ・Stock of each raw material are controlled appropriately taking into account product sales trends and procurement lead times

- ・For some raw materials we make contracts with business partners to secure yearly volumes

Sustainable procurement surveys

- ・Surveys identify risks related to the environment, human rights, occupational safety and health, and anti-corruption based on our CSR Procurement Policy

- ・Each supplier receives feedback based on survey results to boost awareness of CSR and encourage greater sustainable procurement

Supplier general briefing

session

- ・For our suppliers, we held a briefing session for around 400 participants to explain our CSR Procurement Policy and promote sustainable procurement with an awareness of common challenges. (October 2021)

selection

standards

- ・Clear standards for product quality level and response to social and environmental issues are set for the selection of new suppliers

- ・Product quality inspections: To ensure the safe and secure manufacture of high-quality products, we regularly visit manufacturing subcontractors to examine their products and quality management systems

From a supplier’s perspective

Yusuke Toyotomi

Okura Industrial

Co., Ltd.

Environmental issues are our greatest priority

As a supplier of plastic film, we recognize that addressing current environmental issues related to plastic is a top priority.

Focusing on reducing environmental impact together with Yakult Honsha, we reduced the amount of plastic used in shrink-wrap for Mil-Mil multi-pack products by approximately 8%, and last year developed and launched biomass shrink-wrap film for Yakult Hakko Tonyu multi-packs.

We shall continue working together on developments to help achieve the Yakult Group Environmental Vision.

From a Yakult Honsha purchasing manager’s perspective

Makoto Morita

Yakult Honsha

Purchasing

Department

Working towards a value chain with zero environmental impact

Okura Industrial supplies us with various kinds of plastic film for our dairy products and soft drinks, and has been an enormous supporter in addressing our environmental materiality theme of plastic containers and packaging.

The cooperation of Okura Industrial and our other suppliers is essential in achieving the Yakult Group Environmental Vision. We look forward to continuing our partnership!

*As of October 2021